In recent years, electric motors have been rapidly gaining traction as an alternative solution to fossil fuel-powered vehicles, particularly in the automotive and motorcycle sectors. This shift is driven by growing concerns about climate change and air pollution caused by the use of fossil fuels. Electric motors, therefore, present an attractive option due to their efficiency, performance, and lower environmental impact.

This article aims to compare the design of electric motors with that of internal combustion engine (ICE) motors from various key aspects, such as components, energy efficiency, performance, cost, and environmental impact. By providing a deep dive into these comparisons, readers can better understand the differences and why electric motors are becoming an increasingly popular choice in transportation.

1. Design Differences: Electric Motor vs. Internal Combustion Engine

a. Key Components

- Internal Combustion Engine (ICE)

- Complex Mechanical System: An internal combustion engine consists of multiple mechanical components, such as the combustion chamber, ignition system, fuel system, exhaust system, and transmission. This system works by burning fuel (e.g., gasoline or diesel) in the combustion chamber to generate power, which produces exhaust gases that must be expelled through the exhaust system.

- Complexity in Design: The ICE involves additional components like a transmission and a cooling system, making it more complex and requiring more maintenance.

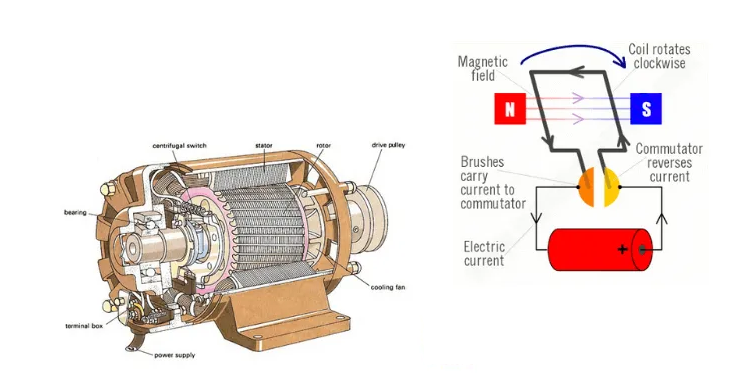

- Electric Motor

- Simpler Components: The electric motor uses a much simpler system consisting of the motor itself, an inverter (to convert DC to AC), and a battery pack. The design of the electric motor is minimal, with fewer moving parts, which reduces the need for regular maintenance.

- Efficiency of Design: With fewer moving parts, electric motors are less prone to wear and tear. There are no exhaust systems or transmissions, which results in a more compact and efficient design.

b. Size and Shape of Design

- Internal Combustion Engine

- Larger, Bulkier Design: Due to the multiple components (engine, transmission, fuel system, exhaust system, etc.), internal combustion engines are typically larger and bulkier. The design of a conventional vehicle with an ICE requires more space to accommodate all these components.

- Impact on Vehicle Design: The need to fit these components into the vehicle forces the overall design to be larger, heavier, and more complex.

- Electric Motor

- Compact and Lightweight: The electric motor is significantly smaller and lighter because it does not require components like the exhaust system or transmission. This allows for a more flexible and streamlined vehicle design.

- Efficient Use of Space: The battery pack can be placed beneath the floor of the vehicle, while the electric motor can be directly mounted on the wheels, eliminating the need for a transmission and offering a more aerodynamic and space-efficient design.

2. Energy Efficiency and Performance

a. Energy Efficiency

- Internal Combustion Engine

- Lower Efficiency: Internal combustion engines are inherently less efficient, with energy conversion efficiency typically around 25-30%. A significant portion of the energy generated from burning fuel is lost as heat, and additional energy is required to power moving mechanical parts.

- Energy Waste: A large portion of the energy in the fuel is wasted as heat and exhaust gases, leading to inefficiency in energy use.

- Electric Motor

- High Efficiency: The electric motor is much more efficient, with energy conversion efficiencies reaching 85-90%. There is no burning of fuel, and the energy from the battery is used directly to power the motor with minimal waste in the form of heat.

- Reduced Energy Loss: Due to the high efficiency of electric motors, they use much less energy for the same distance traveled, which leads to lower operational costs.

b. Performance

- Internal Combustion Engine

- Dependence on Engine Speed: The performance of an ICE is highly dependent on engine speed (RPM), with power output improving at higher revs. Acceleration can be slower, especially at low speeds, as it takes time to build up power.

- Acceleration Lag: The performance is more gradual, with acceleration dependent on reaching higher engine speeds.

- Electric Motor

- Instant Torque: Electric motors offer instant torque, meaning they provide immediate acceleration from the moment the vehicle starts moving. This results in faster and smoother acceleration, especially in city traffic conditions where quick starts and stops are common.

- No Need for Transmission: Since the electric motor provides consistent torque across a wide range of speeds, there is no need for a complex transmission system, which enhances driving comfort and performance.

3. Cost and Maintenance

a. Initial Cost

- Internal Combustion Engine

- Lower Initial Cost: Vehicles powered by internal combustion engines are generally cheaper to manufacture, primarily due to the established technology and the availability of cheaper raw materials. The overall cost of a conventional vehicle is lower because the manufacturing process is well optimized.

- Conventional Manufacturing Process: The simplicity of the engine and the widespread use of fossil fuel-powered vehicles keep the initial production cost lower.

- Electric Motor

- Higher Initial Cost: Vehicles with electric motors tend to be more expensive initially, largely due to the cost of lithium-ion batteries. These batteries represent a significant portion of the cost, although battery prices are steadily decreasing as technology improves.

- Impact on Vehicle Pricing: Although electric motor vehicles are more expensive up front, technological advancements are likely to reduce prices over time, making electric vehicles more competitive.

b. Operational Costs and Maintenance

- Internal Combustion Engine

- Higher Operational Costs: Gasoline or diesel-powered vehicles incur higher operational costs due to fluctuating fuel prices. Regular maintenance, such as oil changes, exhaust system checks, and air filter replacements, increases the cost of ownership.

- Frequent Maintenance: Conventional engines require routine maintenance for components like the engine, transmission, and fuel system to ensure optimal performance.

- Electric Motor

- Lower Operational Costs: Electric vehicles (EVs) have much lower operating costs due to the relatively low cost of electricity compared to fossil fuels. Additionally, maintenance costs are lower since the electric motor has fewer moving parts, reducing wear and tear.

- Minimal Maintenance: EVs do not require oil changes, and there are fewer parts to maintain. Battery checks and occasional software updates are the primary forms of maintenance needed for electric motors.

4. Environmental Impact

a. Carbon Emissions

- Internal Combustion Engine

- Pollution and Emissions: Fossil fuel-powered vehicles emit harmful gases such as carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter, all of which contribute to climate change and air pollution. Every time the vehicle runs, emissions are released into the atmosphere.

- Contribution to Global Warming: The use of fossil fuel-powered vehicles is a significant contributor to the greenhouse effect and global warming.

- Electric Motor

- No Direct Emissions: Electric motors do not produce emissions while driving, making them a cleaner option, especially in urban areas. However, there is still an environmental impact associated with the production of electricity, depending on the energy sources used (fossil fuels or renewable energy).

- Lower Overall Carbon Footprint: Even when accounting for the energy required to produce and charge electric vehicles, the overall carbon footprint of EVs tends to be lower compared to fossil fuel-powered vehicles, especially when the electricity is sourced from renewable sources.

b. Recycling and Sustainability

- Internal Combustion Engine

- Difficult to Recycle: Many components of an internal combustion engine are difficult to recycle, and most fossil fuel-powered vehicles eventually end up as waste when they reach the end of their lifespan.

- Waste at End of Life: After the vehicle is no longer functional, disposal of the materials used in conventional engines can pose environmental challenges.

- Electric Motor

- Battery Recycling Challenges: Although electric motors are generally cleaner during operation, the batteries used in electric vehicles present recycling challenges. Lithium-ion batteries can be hazardous if not properly managed, but ongoing advancements in battery recycling technologies are improving this aspect.

- Potential for Greater Sustainability: As battery recycling methods improve, and as the energy mix becomes greener, electric vehicles could offer a more sustainable solution overall.

- Advantages of Electric Motors:

- Electric motors are more energy-efficient, environmentally friendly, and have lower operational costs. Their simpler, more compact design provides flexibility for vehicle design and ease of maintenance.

- Drawbacks of Electric Motors:

- The higher initial cost of electric vehicles, mainly due to the price of batteries, remains a barrier. Furthermore, charging infrastructure is still being expanded to support the widespread adoption of electric vehicles.

- Advantages of Internal Combustion Engines:

- The lower initial cost and established infrastructure for fuel make vehicles with internal combustion engines more affordable and convenient in the short term. However, their higher environmental impact and operational costs present challenges for the long-term future.

- Drawbacks of Internal Combustion Engines:

- The environmental pollution, inefficiency, and long-term operational costs make fossil fuel-powered vehicles less sustainable compared to electric motor vehicles.